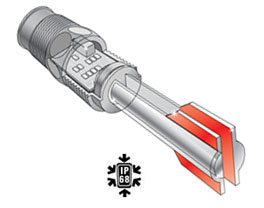

| The general purpose vibration level switch is a great choice for dirty liquids including those with light to medium coating, scaling or foaming characteristics. Media examples include wastewater, diluted caustic soda and light weight oil. For optimum performance and proactive maintenance, the sensor automatically adjusts for coating build up, and if necessary, outputs a preventative maintenance alarm. The submersible sensor is universally mounted through the wall or inside the tank. |

|

|

|

Automatic coating adjustment optimizes sensor performance |

|

Rugged Ryton® probe with Viton® and PP cable rated NEMA 6 |

|

Coating preventative maintenance alarm saves time and money |

|

1A relay selectable NO or NC via power supply wiring polarity |

|

| Tech Tip |

| Using advanced self-learning technology, the level switch automatically adjusts to increased material build-up on the forks for maximum coating performance. If the coating becomes too significant, then the sensor will actuate a transistor alarm for proactive maintenance. |

|

|

|

Specifications

|

|

Orientation:

|

Universal

|

|

Repeatibility:

|

± 0.5 mm in water

|

|

Supply voltage:

|

12-30 VDC

|

|

Contact type:

|

(1) SPST relay (NO/NC)

|

|

Contact rating:

|

60 VA

|

|

Maintenance alarm:

|

NPN transistor,

10 mA max.

|

|

Process temp:

|

F: -40° to 176°

C: -40° to 80°

|

|

Pressure:

|

150 psi (10 bar)

|

|

Cable length:

|

10' (3m)

|

|

Sensor rating:

|

NEMA 6 (IP68)

|

|

Process mount:

|

3/4" NPT (3/4" G)

|

|

Sensor material:

|

Ryton® (glass filled),

Viton® cable grommet

|

|

Classification:

|

General purpose

|

|

|

|